EQUIPMENT LIST

CNC Mills

Our CNC equipment provides us with the competitive advantage needed to provide you with high quality precision work that meets your unique production or tooling needs.

All CNC mills run on 3D modeling software to ensure the most accurate cut the first time.

|

||

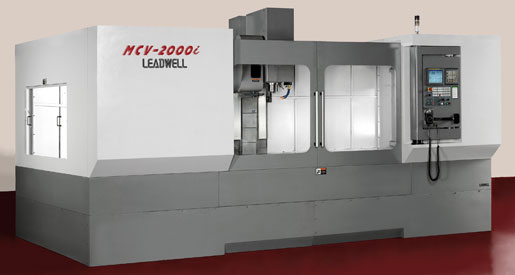

| Leadwell MCV-2000i is capable of 4-axis milling of large parts up to 40" x 80". An onboard 30-tool changer makes this machine great for both long or short runs. Rapid milling ensures parts are done with less lead time. | ||

|

|

||

Two CNC tool room mills are capable of 3-axis milling parts to 20” x 40”. Great for short run production and prototype work.

|

Leadwell V-40 is capable of 4-axis milling of parts up to 20” x 40”. Onboard 24-tool changer. Great for short or long run production along with prototype work. Rapid milling feature ensures parts are done with less lead time.

|

||

CNC Lathe & Wire EDM

Both CNC Lathe and Wire EDM use MasterCAM for all their programming.

|

|

|

| Samsung SL25BMC features a machining length of 40" between centers. With an onboard 12-Tool changer and 14-3/8" max. outer diameter cutting area it is the perfect machine to complete those difficult larger cuts more efficiently. Rapid machining and live tooling give it the added aspect of completing parts with shorter lead time. Great for long or short production and prototyping work. |

Fanuc Robocut Wire EDM is a submersible wire that features quicker cut times and higher accuracy. Perfect for die details and parts that require tight clearances. Max. height: 10 in. Max. piece size: 15-3/4" x 23-5/8". Max. taper: 30° |

Manual Equipment

|

(2) Radial Arm Drill Presses: (5) Manual Mills: (6) Surface Grinders: (1) O.D. Grinder: (1) Jig Grinder: (3) Manual Lathes: |